Model Composition of Vacuum Valve

The correct selection of valve model and specifications requires understanding of the method of preparing vacuum valve models; the method of preparing vacuum valves of our company is basically similar to ZBJ78016-89 “Vacuum Valve Models and Methods of Preparation”. The product model is composed of two parts: the basic model and the auxiliary model, separated by a dash, the model composition is as follows:

Represents the vacuum degree range of the product, expressed by the first letter of its keyword Hanyu Pinyin (printed capital)

- The range of representative vacuum degree is: low vacuum 105~10-1Pa (760~10 Torr) with-D;

- The representative vacuum range is: 105~10-4Pa (760~10-6 Torr) for high vacuum—G;

- The representative vacuum range is: ultra-high vacuum 10~10-7Pa (760~10-9 Torr) with-C;

Represents the structure of the valve plate or the functional category of the product, and is represented by the first (or second) letter (printed capital) of its keyword Hanyu Pinyin as:

C plug-in valve, Q inflation valve, D flapper valve, U ball valve, F flap valve, W fine-tuning valve, I butterfly valve, Y differential pressure valve, M diaphragm valve;

Represents the product-driven approach, expressed by the first letter of its keyword Hanyu Pinyin (printed capital):

S manual, D electric, Q pneumatic, C magnetic, Y hydraulic;

Represents the form of the valve channel, represented by the first letter of its keyword Hanyu Pinyin (printed capital):

Z straight-way valve, J angle-way valve, S three-way valve;

Special case: Only valves with inflation are coded with the Chinese pinyin capital letter Q, and other types of valves are not coded with symbols.

Representative product specifications-nominal diameter, expressed in Arabic numerals, the unit is (mm):

Such as: DN 16mm, 100mm, 500mm, etc. are represented by 16, 100, 500, etc.

Special case: Very few products use Arabic numerals to indicate their performance parameters. For example, “30” in the model of the GW-30-T high vacuum fine-tuning valve means that the maximum adjustable amount of the high-vacuum fine-tuning valve is 30 Torr.L/S.

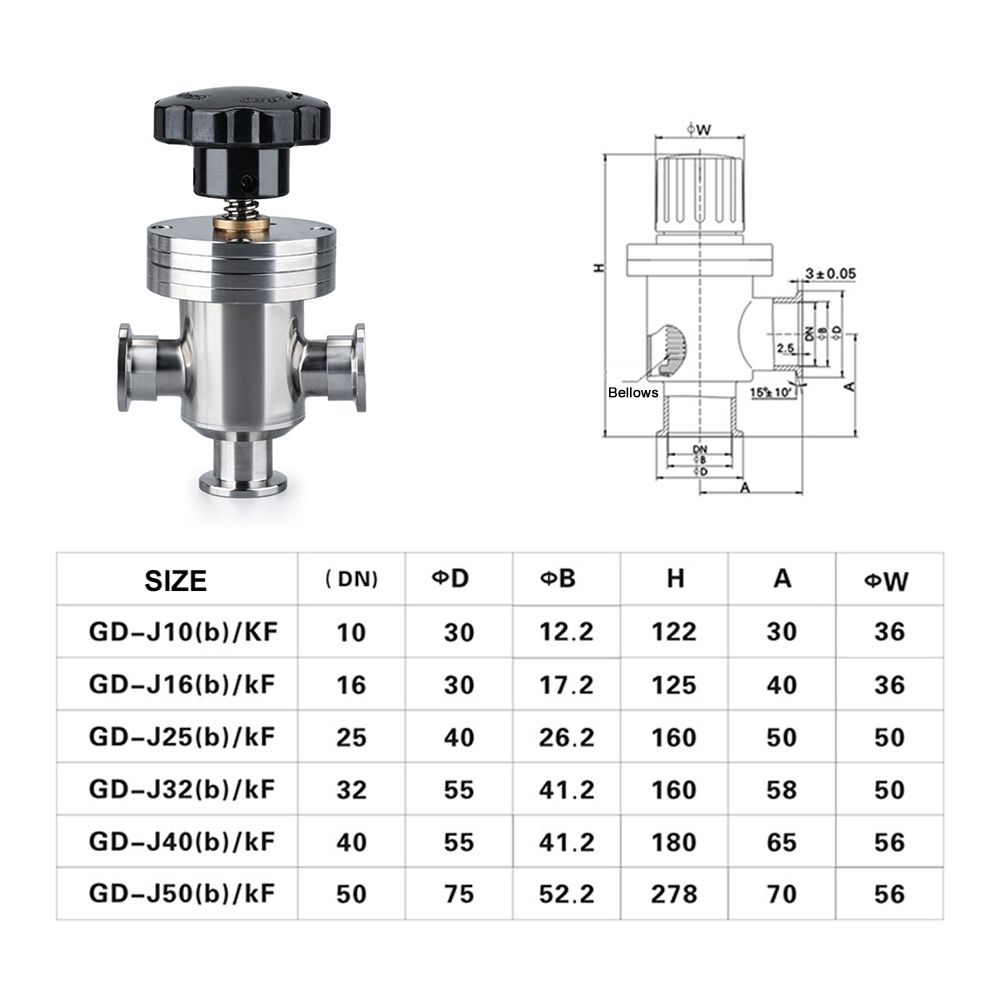

The corner note represents the seal structure of the shaft seal. At present, only the stainless steel bellows is used for the shaft seal with the Chinese pinyin lowercase letter b as the code. Other seal structures (such as rubber seals, PTFE, etc.) are not represented by letters.

Only individual products (such as vacuum (pressure) ball valves) use bracketed capital English letters to indicate the connection method or the code of the valve’s main sealing and secondary material.

(KF) means adopting the standard of GB4982 “Clamping Vacuum Quick Release Flange”, (G) means adopting the standard of GB7306 “Cylindrical Pipe Thread”, (F) means adopting the standard of GB6070 “Looping Vacuum Flange”, (JB) means Using JB919-75 “Vacuum Flange” standard H or H(Ⅰ) means that the two ends of the valve are welded, and H(Ⅱ) means that one end of the valve is welded, and the other end is a plug with a rubber tube. ;

By analogy of the products designed for the first time, here are a few examples:

- GM-25H(Ⅰ) High vacuum diaphragm valve, nominal diameter 25mm, welding structure at both ends.

- CCQ-150 pneumatic ultra-high vacuum flapper valve, nominal diameter 150mm.

- GID-250 electric high vacuum butterfly valve, nominal diameter 250mm.

- GUQ-40 (KF) pneumatic high vacuum (pressure) ball valve, nominal diameter 40mm, connection method is GB4982 “clamping vacuum quick-release flange” DN40 quick-release flange.

- GD-J100b high-vacuum flapper valve, nominal diameter is 100mm, the conduction type is angle type, and the shaft seal is stainless steel metal bellows.

- DYC-JQ50 electromagnetic vacuum differential pressure valve, nominal diameter is 50mm, and the conduction form is angle type. (Low vacuum generally only needs the word “vacuum”).

- DDC-JQ80 electromagnetic vacuum belt inflation valve, nominal diameter 80mm, conduction form is angle type. (Low vacuum generally only needs the word “vacuum”).

- GDC-J25b electromagnetic high vacuum baffle valve, nominal diameter is 25mm, and the conduction form is angle type. The shaft seal is a stainless steel metal bellows.

The vacuum valve has the following characteristics:

The pressure is lower than atmospheric pressure, and the pressure drop on the disc cannot exceed 1 kgf/cm2. The working temperature of the medium depends on the process of using the device. The temperature generally does not exceed the range of -70 ~ +150℃.

The most basic requirement for this type of valve is to ensure a high degree of sealing of the connection and the compactness of the structure and gasket material.

According to the medium pressure, the vacuum valve can be divided into four groups:

1) Low vacuum valve: medium pressure p=760~1mmHg.

2) Medium vacuum valve: p=1×10-3 mmHg.

3) High vacuum valve: p=1×10-4 ~1×10-7 mmHg.

4) Ultra-high vacuum valve: p≤1×10-8 mmHg.

As a closed-circuit valve with a diameter less than 250 mm, the widely used vacuum bellows stop valve with a linear movement of the stem is widely used. Gate valves are subject to greater restrictions, but this is mainly for large diameters. Also available are ball plug valves (ball valves), plunger valves and butterfly valves. The plug valve used as a vacuum valve has not been promoted, because the plug valve needs to be lubricated with oil, so that oil and vapor may enter the vacuum system, which is not allowed. The vacuum valve can be controlled by hand and remote control on site, as well as by electric, electromagnetic drive (solenoid valve), pneumatic and hydraulic control.