How to Make Cylindrical Cell

SaveSavedRemoved 0

Deal Score+4

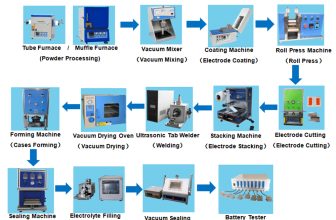

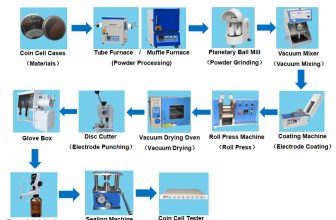

Step 1: Electrode Sheet Preparation

- Use furnace to sinter raw cathode active material and anode active material.

- Use milling machine to mill materials into smaller-sized particles.

- Mix active, conductive and binder material into paste under vacuum using mixer.

- Use a coater to coat paste onto current collector to create electrode.

- Use a heater to dry the newly-created electrodes.

- Use the rolling press (calendar) to roll the electrode to required thickness.

Step 2: Li-ion Cell Assembly

Winding Method

- Use Slitting Machine to slice electrode sheet into strips.

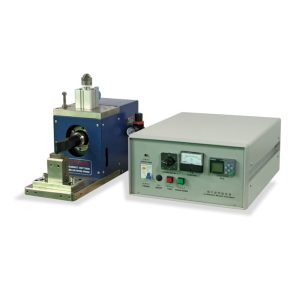

- Weld current collector and tab together using Ultrasonic Welding Machine.

- Use Winding Machine to wind strips of Anode, Separator and Cathode into cell core.

- Use Short-Circuit Detector to test the cell’s integrity.

- Dry the cell using a vacuum oven.

Step 3: Formation & Sealing of Battery Case

- Use Deep Spot Welding Machine to weld one tab from the cell to the bottom of the closing end inside cylinder case.

- After inserting the cell core, use Grooving Machine to groove cell case and fix location of battery core for later sealing.

- Use Welding Machine to weld the other tab from the cell to the cap.

- Fill the case with electrolyte in vacuum/globe box using Electrolyte Filling System.

- Insert & align the cap to open end of case and seal the opening using Sealing Machine inside glove box.

- Using Battery Analyzer, charge and discharge the assembled battery to activate the cell.

- Wrap the case with heat-shrinkable PVC for isolation of positive & negative terminals.

Step 4: Battery Testing

- Test the newly-created battery’s performance using a Battery Analyzer.

- Use an Impedance Tester to measure the battery’s internal resistance.