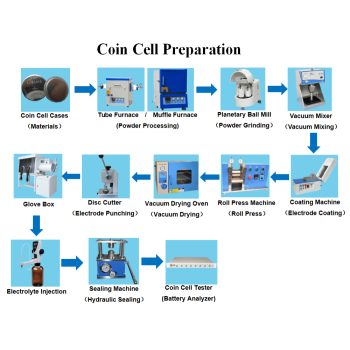

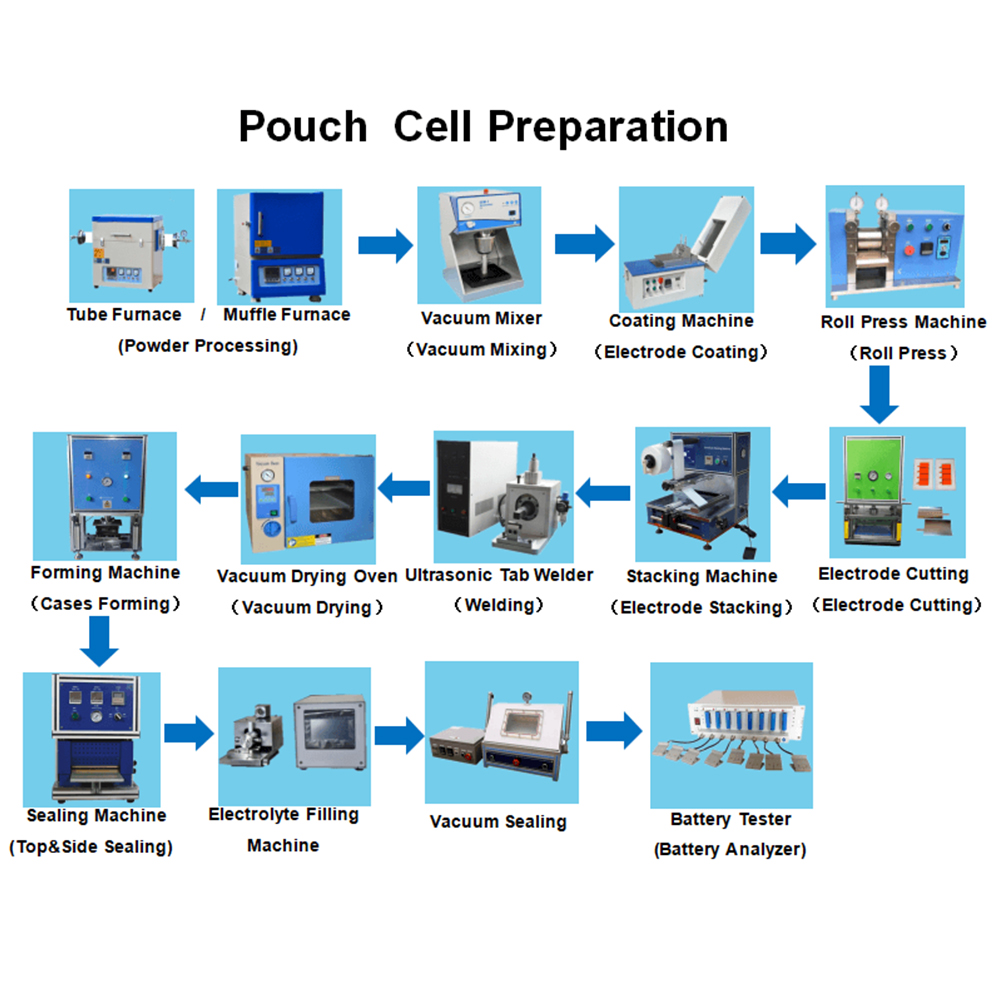

Step 1: Electrode Sheet Preparation

- Use furnace to sinter raw cathode active material and anode active material.

- Mill battery materials into smaller particles using milling machine.

- Use mixer to mix active, conductive and binder material into paste under vacuum.

- Using coater, coat paste onto current collector to make electrodes.

- Dry the newly-created electrodes using a heater.

- Use the rolling press (calendar) to roll the electrode to desired thickness.

Lab Hot Roller Press Machine

Original price was: $4,900.00.$4,700.00Current price is: $4,700.00. -4%Step 2: Li-ion Cell Assembly

- Use Disc Cutter to cut single coated anode, cathode andseparator into disc shape.

- Use a Pressing Machine to flatten the disc.

- Soak discs into electrolyte in glove box with H2O and O2 below 1ppm.

- Stack the discs in the order found in the coin cell case.

- Dry the cell using a vacuum oven.

- Fill the appropriate amount of electrolyte into the case using Electrolyte filler.

- Use a Crimping Machine to crimp the coin cell to seal the battery core within the case.

Laboratory CR2016 CR2025 CR2032 Manual Coin Cell Crimping Machine Tool

Original price was: $2,980.00.$2,550.00Current price is: $2,550.00. -14%Step 3: Li-ion Battery Testing

- Test the li-ion coin cell’s performance using the battery analyzer.

- Measure the battery’s internal resistance using an impedance testing tool.

How to make a coin cell

This describes how to build a coin cell battery using a novel cathode material and lithium anode.