Description:

The oven has a stainless steel inner tank, and each studio works independently. The working mode of heating, vacuuming and inflating is automatic circulation, and the time of each working period is set through the touch screen. The oven adopts PLC control system, touch screen operation, flow blast heating and heat dissipation. The heating time is short, the heat dissipation time is fast, and the pressure holding effect is good. Heating method: heat radiation, heat conduction, heat exchange, heat convection.

Feature:

* The equipment is compact and reasonable in structure, beautiful in appearance and small in space.

* The equipment is easy to operate, no professional training is required, and workers can easily master it.

* The equipment adopts text control valve, vacuum pumping and nitrogen filling, high efficiency, saving personnel, and good product performance.

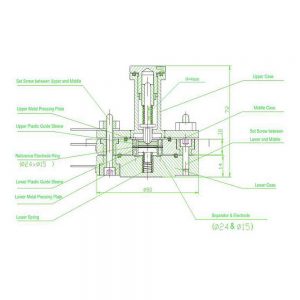

* The equipment is divided into upper, middle and lower three layers, 3mm thick high-quality stainless steel inner tank, strong corrosion resistance, single door and single control (each layer can be controlled separately), and does not affect each other.

* The equipment is equipped with universal movable casters, so the equipment can be moved easily when shifting.

* The equipment adopts 304 stainless steel heating tube coiled inside the inner tank heating type, temperature control is uniform, the equipment has 80 °C, 100 °C, 120 °C and other temperature monitoring points to monitor the temperature before leaving the factory, so as to achieve the temperature of each device All should be uniform at different times.

* The equipment is sealed with silicone rubber sealing strips, 15mm thick tempered glass is used as the door, and each door is designed with an observation window.

* The electrical cabinet is on the side. Each inner cavity has 2 stainless steel brackets equally divided into 3 layers (layer height 103mm).

* The elastic double-layer glass door has overvoltage protection.

* The screen adopts a touch screen for centralized operation, which is convenient for operation and reliable for control.

* Including operator password.

Technical parameter:

*Oven temperature: normal temperature~160°C (can be set).

*Inner tank temperature error: ±3°C (no load) (baking temperature 100°C).

*Heating time: The temperature stabilization time of the core without load is 60 minutes.

*Surface temperature: The surface of the equipment is ≤45°C when working at 100°C.

*Main heating temperature control: display temperature error within 1°C.

*Main heating heating control: the safety switch is set to 150°C during heating (automatically adjustable).

*Before leaving the factory, the equipment adopts 5 points inside the inner tank to check the temperature uniformity, and the inner tank and display temperature can be controlled within ±2°C.

*Include circulating air system, capable of process programming and automatic control.

*With high temperature alarm function, automatic over temperature alarm.

* Drying box frame material: made of high-quality thick cold-rolled plate.

*Inner cavity material of drying box: all made of 3mm thick high-quality stainless steel.

*Electrical control device: It is controlled by solid state relay and made of brand electrical accessories.

*With automatic protection function for power failure.

*Baking method: heating tube surrounds the inner tank for heating, hot air circulation.

* Vacuum holding time: ≥98% after 24 hours in the case of -0.1MPA.

*Vacuum degree: -0.1Mpa.

*Power source: 380V/AC, 110V/AC. Total power: 8KW.

*Inner tank specifications: 660 (width) × 750 (depth) × 330 (height) mm.

*Oven dimensions: 1280 wide × 1150 deep (including fan 120) × 1900 high mm.

*Weight: 850kg.